321 Mandrel Bends Available Now!

ABOUT ACE RACE PARTS 321 STAINLESS STEEL ELBOWS

Ace Race Parts 321 Stainless Steel Mandrel Bends are manufactured in an ISO 9001 certified facility and are the highest quality and lowest price 321 Stainless Steel bends available in the automotive, industrial, and marine markets today. Our 321 Stainless Mandrel Bends are manufactured to the ASTM A270 specification and offer a clean, high quality welding experience due to an extensive testing and inspection process prior to shipment. Our 321 Stainless Mandrel Bends is an exceptional choice for high performance, lightweight, and high temperature exhaust systems and other automotive applications.

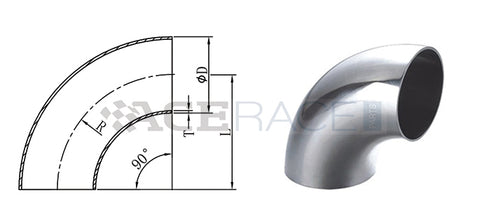

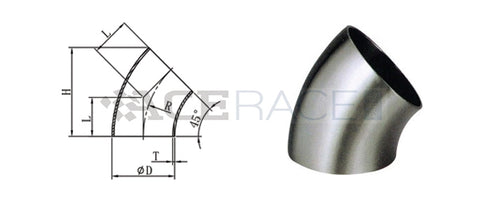

Ace Race Parts 321 Stainless Mandrel Bends are available in outside diameter ranges from 1.500" to 3.000" and are available in both 45° and 90° bend degrees. With a high quality brushed finish on the outside of the bends, our 321 Stainless Mandrel Bends offer a high quality welding experience and is ensured to fit perfectly with our 321 Stainless Tubing, 304 Stainless V-Band Clamps & Flanges, 304 and 321 Stainless Flex Couplings and Flex Bellows, Stainless Bungs, and Stainless Exhaust Flanges.

WHAT IS 321 STAINLESS STEEL?

321 Stainless Steel, like 304 Stainless Steel, is a low carbon, chromium nickel alloy with good intergranular corrosion resistance. 304 Stainless has good corrosion resistance up to 1,562°F (850°C); whereas, 321 Stainless allows for a higher temperature limit, including long term exposure to high temperatures, up to 1,652°F (900°C) due to the addition of Titanium, which acts as a stabilizer. 321 Stainless Steel's main advantage over 304 Stainless Steel in high temperature environments is that 321 Stainless offers better resistance to stress fractures. This higher resistance to stress fractures has advantages in automotive applications where differences in the Coefficient of Thermal Expansion (heat-related expansion and contraction which occurs at different rates) are greatest — typically between the engine and the manifold(s). 321 Stainless is better suited to handle this type of heat-related stress, as compared to 304 Stainless. While 304 Stainless is suitable for a wide variety of automotive applications, 321 Stainless is the superior choice for high temperature applications, and especially applications that see long term exposure to high temperatures like race cars, and offers a higher resistance to stress fractures and heat-related corrosion. For welding 321 Stainless Steel (including welding 321 Stainless to 304 Stainless) we recommend ER347 Filler Rod.

90° MANDREL BENDS 321 STAINLESS - POLISHED FINISH

| SKU | DESCRIPTION | MSRP |

| 21214 | 1.500" 16ga 90° Mandrel Bend 321 Stainless | $15.00 |

| 21215 | 1.625" 16ga 90° Mandrel Bend 321 Stainless | $18.00 |

| 21216 | 1.750" 16ga 90° Mandrel Bend 321 Stainless | $19.00 |

| 21217 | 2.000" 16ga 90° Mandrel Bend 321 Stainless | $23.00 |

| 212-225 | 2.250" 16ga 90° Mandrel Bend 321 Stainless | $27.00 |

| 21218 | 2.500" 16ga 90° Mandrel Bend 321 Stainless | $31.00 |

| 21218-B | 2.500" 16ga Tight Radius 90° Mandrel Bend 321 Stainless | $31.00 |

| 21219 | 3.000" 16ga 90° Mandrel Bend 321 Stainless | $42.00 |

| 21219-B | 3.000" 16ga Tight Radius 90° Mandrel Bend 321 Stainless |

$42.00 |

| 212-350 | 3.500" 16ga Tight Radius 90° Mandrel Bend 321 Stainless | $57.00 |

45° MANDREL BENDS 321 STAINLESS - POLISHED FINISH

| SKU | DESCRIPTION | MSRP |

| 21204 | 1.500" 16ga 45° Mandrel Bend 321 Stainless | $13.00 |

| 21205 | 1.625" 16ga 45° Mandrel Bend 321 Stainless | $16.00 |

| 21206 | 1.750" 16ga 45° Mandrel Bend 321 Stainless | $17.00 |

| 21207 | 2.000" 16ga 45° Mandrel Bend 321 Stainless | $21.00 |

| 212-225-B | 2.250" 16ga 45° Mandrel Bend 321 Stainless | $24.00 |

| 21208 | 2.500" 16ga 45° Mandrel Bend 321 Stainless | $29.00 |

| 21209 | 3.000" 16ga 45° Mandrel Bend 321 Stainless | $39.00 |

| 212-350-B | 3.500" 16ga 45° Mandrel Bend 321 Stainless | $55.00 |

Leave a comment